1. DCIM

| Overview

DCIM operation support portal service required for data center management is supported.

Provide customized SRMS (Server Rack Management System) operation information to customers in real time by linking

real-time data of facilities and power system

| Function

Data integration of unit system data required for data center operation on a platform basis

- Electrical Equipment, Air Conditioning Equipment, Fire Equipment, Power/Lighting, Water Leakage, Glass Destruction, Access Control, CCTV

- Industry standard protocol (BACnet, Modbus, OPC, SNMP, etc.) interface support

Various dashboard-type operating screens are provided.

Implementation of emergency scenarios through interworking between heterogeneous events

- Composition of operation screen based on data standardization and graphic design tool

- Providing customized dashboard screens for customers to support energy efficiency management

- Provide emergency scenarios by accommodating all customer requirements

Provides a setting function optimized for data center management for each customer and provides convenience of operation (Excel registration)

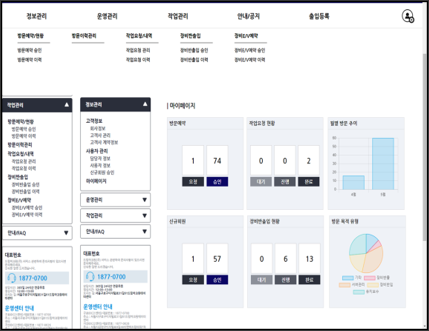

DCIM(Data Center Infrastructure Management) dedicated web portal service

| Sample Screen

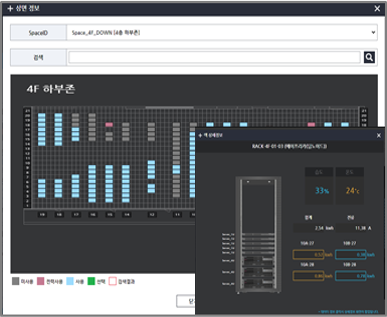

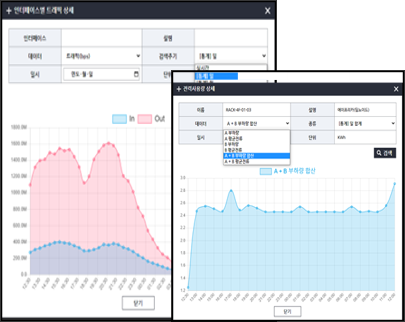

[Operation Management-Rack Details]

[Operation Management-Power Stat]

[Web DCIM main screen]

| Applications Field

- Data Center Web Portal Service

- Real-time data linkage using the platform

| Reference

- DreamMK1- DICM and web service

2. SI Solution

| Overview

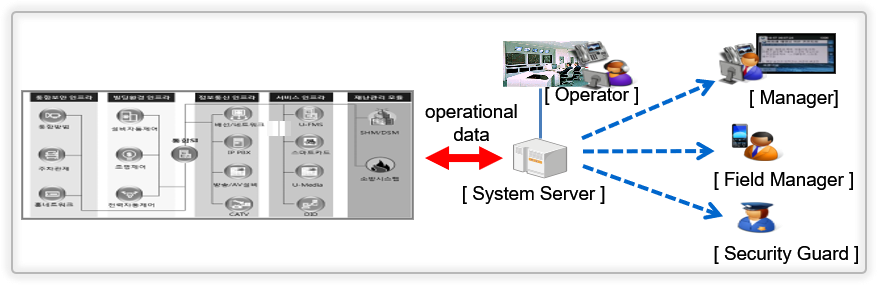

A system for monitoring and managing the entire facility operation status.Integrated control operation center support system that supports emergency

controllers to quickly determine and respond to situations through the integration of important operational data

such as firefighting/electric power/elevator/access control/CCTV

| Background

It is difficult to interoperate with each unit system event, and the limitations of the existing system that require developers when modifications occur

There is a need for a solution that can build integrated data through interworking with each unit system without a developer and integrate

operation of various response scenarios, etc

| Function

Interface with unit system through industry standard interface protocols such as BACnet/OPC/Modbus, which are industry standard interface modules

Detailed monitoring and control of all process - Event Declaration/Process/Complete.(Intelligent Monitoring & Control System)

History management of all events - Status Change, System Failure, Failover

Easily and freely create control scenarios (Intrusion detection->Lighting Control->CCTV Record->Notify to Manager)

Systematic alarm management and response scenarios for all equipment

Graphic design tool for support creating & change operation display design frame in flexible way

| Sample Screen

| Applications Field

- Efficient facility operation management

- Establishment of control system for operation data integration

| Reference

- National Rehabilitation Center Integrated SI , Rescue Location Information Display

- Hyundai Motor Goyang Complex Base Integrated SI

- Garden 5/ Gimpo Hyundai Premium Outlet Integrated SI

- Hyundai Powertech(China) SI/VMS/Access Control/Emergency Bell

- Dreammark One DCIM Service

- Web service development application

3. Access Control

| Overview

Real time access status monitoring and convenient card registration function

| Background

In the case of HID (Access Control Solution), only API is provided, and only 1-2 domestic companies have interworking experience

The need for a security solution that integrates HID equipment, CCTV, and various sensors

| Function

Automatic registration possible through the device search function (ACU registration in just 1~2 steps)

Provides perfect linkage to HID. ACU/Interface/Reader/Port can be set without a separate program.

Full access control system API support, SDK can be provided to external solution

Provides a management program focused on the convenience of card registration. Card information registered in the existing ACU can be used

Provide interworking with external system and automatically show video when event occurs

Provides various access control monitoring screens through screen design programs

| Sample Screen

[AC registration/management]

[AC operation screen-T&A management]

| Applications Field

- CCTV Video and Access Control Integration

- HID access control and In/Out port control

| Reference

- Hyundai Powertech ( China ) Access Control /CCTV/ Emergency Bell

- Serve One Logistics Center ( Vietnam ) Access Control / CCTV

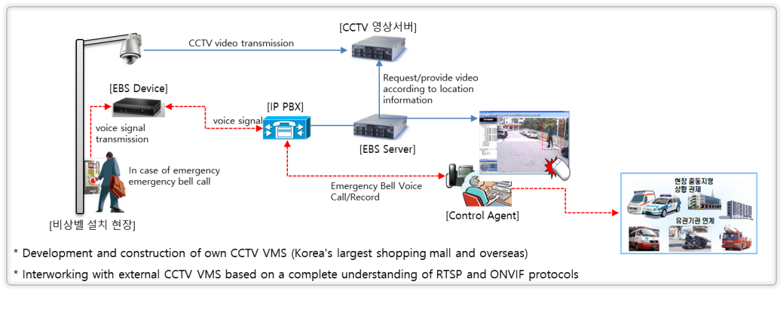

4. Emergency Bell

| Overview

IP phone (SIP protocol) type IP emergency bell integrated system . A system that supports quick rescue requests and responses in emergency situations by linking with the CCTV system and connecting to the control center in real time in case of an emergency

| Background

Development of emergency bell system using experience in managing more than 5000 IP phones and all functions related to MCU and IPCC

(call distribution, IPIVR, coloring, recording) and CCTV solution

| Function

Various voice data processing experience

Operation event history management

Interface with various additional Solutions

Built-in Contact Center System

Rapid fault detection

Easy fault and system maintenance

Voice and Video support

| Applications Field

- External emergency bells and CCTV connections in parks and alleys

- Emergency bell systems such as parking lots or toilets in buildings

| Reference

- Incheon Dong-gu Office Emergency Bell System

- Hyundai Powertech ( China ) Emergency Bell / CCTV

- Ulsan Honorsville Apartment Parking Lot Emergency Bell / CCTV

5. TMB

| Overview

The TMB (Telephony Multimedia Board) solution is a digital monitor display service that displays various information by interworking with additional solutions of the IP phone system.

| Background

Inconvenience of using a paper-printed organization chart whenever a company reorganizes or transfers personnel

Electronic organization chart linked with integrated platform graphic editing function and existing IPT phone solution

| Function

Instead of printing on paper, display screens provide a variety of information

Information can be edited by users and administrators. Respond quickly to personnel movements and reorganization

Status information can be changed on the user's phone

User status can be displayed using icons, strings, different colors, and more

User status can be displayed using icons, strings, different colors, and more : Organization chart, promotional video, Evacuation Guide

Organizational chart can be changed only by changing the setting without the need for separate printing.

Use the screen design tool to edit the desired operation screen

| Sample Screen

[Building Guide Screen]

[Department Location Guide]

[Organization Chart]

| Applications Field

- Public offices and companies with a lot of personnel transfer / reorganization

- Expected to increase work efficiency by providing information on the working status of workers

| Reference

- Incheon Waterworks Headquarters and Offices Electronic Guide Map

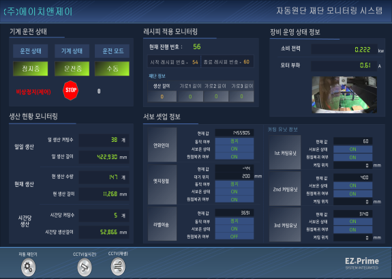

6. Smart Factory

| Overview

Implementation of integrated control of production facilities and MES/POP function based on the integrated platform

| Background

Difficulty in interface with production facilities in the existing MES SW when building a smart factory

It is necessary to implement the MES function using the integrated platform and the integrated control function for production facilities

| Function

MES function ( standard information management , production management , quality control , inventory management , facility management , system management )

Inventory management through barcode linkage ( product arrival , shipment, etc. )

Production facility interlocking control using integrated platform (PLC/ Modbus interlocking , CCTV interlocking )

Real-time monitoring and control of automation device progress ( equipment operation status information , remote control )

Monitoring of automated equipment production performance by period (daily, monthly)

Real-time monitoring of equipment operation status through CCTV connection

| Sample Screen

[Production facility operation monitoring]

[MES/POP Example Screen - Product Status ]

| Applications Field

- Integrated control of smart factory automation production facilitiess

- Linking MES/POP and production facilities using the platform

| Reference

- Smart Factory - Construction site safety net fabric automatic cutting machine